The Technology

Amorphous metal technology was originally developed for space travel and is commonly referred to as metallic glasses. The amorphous element is produced by cooling molten alloy at aproximately 1,000,000 degrees per second. This rapid cooling forces the alloy to lose its normal crystalline structure and an amorphous molecular structure is formed.

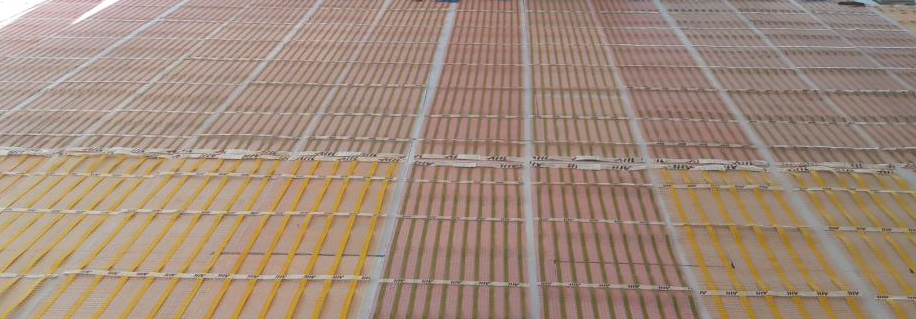

The amorphous ribbon element is 25 microns thick (1/40th of a millimetre) and when manufactured into a heating ribbon, measures just over 1mm thick including two layers of insulating material. This double insulation allows the system to be defined as a "Class11"* appliance, simplifying the installation process even further. The system has comprehensive accreditation including BS, UL, CE, NEMKO, IEC etc. and is represented in over 70 countries worldwide.

Heating a property using amorphous technology is comfortable and economic as it heats occupants via radiant heat rather than convective heat. It has inherrently high energy transfer capabilities and does not suffer from fatigue the same way a standard copper heating wire does. The element is extremely robust, very flexible and responds quickly to thermostatic control via a touch panel thermostat, through an app on a smartphone/tablet or by voice control via Amazon Alexa or Google Home.

* A Class 11 or double insulated electrical appliance is one which has been designed in such a way that it does not require a safety connection to electrical earth (ground).